Unconfined Compressive Strengths in Geotech Engineering

Did you know that the Unconfined Compressive Strength (UCS) test is a crucial element in ensuring the safety and stability of structures in geotechnical engineering?

Soil analysis is a vital component of geotechnical engineering, and the UCS test plays a significant role in providing valuable data for assessing the strength of the soil. By measuring the maximum axial compressive stress that a specimen can bear under zero confining stress, engineers can make informed decisions regarding construction techniques and design analysis.

Key Takeaways:

The Unconfined Compressive Strength (UCS) test is used to measure the strength of rock specimens or fine-grained soils.

It provides valuable data for geotechnical engineering and soil analysis.

The UCS represents the maximum axial compressive stress a specimen can bear under zero confining stress.

The test also measures axial and lateral deformation to derive the sample's elastic modulus and Poisson's ratio.

The UCS is vital in the design and stability analysis of foundations, retaining walls, slopes, and embankments.

Laboratory Procedure for Unconfined Compression Test

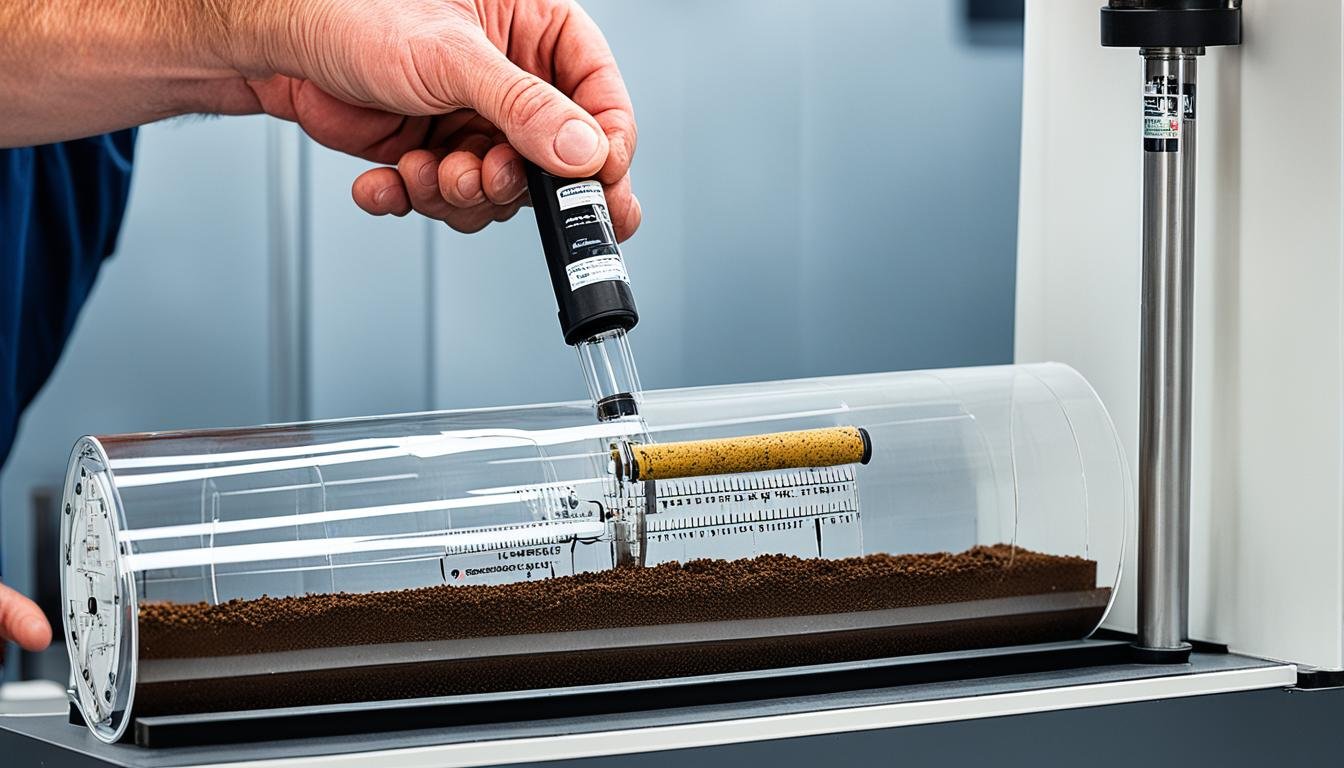

In order to conduct the Unconfined Compression Test, a precise and detailed laboratory procedure must be followed. The procedure involves careful sampling and appropriate specimen preparation using specific apparatus.

Sampling

The first crucial step is sampling. Samples for the Unconfined Compression Test are typically obtained through drill cores and must accurately represent the original rock formation. It's essential to ensure that the samples are representative of the site being studied, as this will impact the reliability and accuracy of the test results.

When sampling, the diameter of the specimen is a crucial factor. To ensure reliability, the diameter of the specimen should be at least 47 millimeters and ten times larger than the size of the largest mineral grain present in the sample. Additionally, the length-to-diameter ratio of the specimen should meet the specified ranges according to standards. This ensures that the sample is suitable for testing.

The surfaces of the cylindrical samples should be flat and smooth, with leveled ends. This is vital for accurate loading and measurement during the test. The quality of the sample surface preparation significantly impacts the test results, so attention to detail is crucial.

It is important to note that a sufficient number of samples should be taken to ensure reliable Unconfined Compressive Strength (UCS) values. At least five samples are generally required for a comprehensive analysis.

Apparatus

The Unconfined Compression Test requires specific apparatus to ensure accurate and reliable measurements. The standard apparatus used for the test includes:

A loading device: This device applies a specified load to the specimen during the test. It is essential for measuring the specimen's compressive strength.

Platens: The platens, typically made of stainless steel, provide support to the specimen during loading. They ensure that the axial load is evenly distributed across the specimen's ends.

Strain measurement devices: These devices are used to measure axial and lateral deformation in the specimen. They provide important data for calculating the sample's elastic modulus and Poisson's ratio.

The proper selection and calibration of the apparatus used in the Unconfined Compression Test are critical to obtaining accurate and reliable results.

Testing Procedure for Unconfined Compression Test

Before conducting the Unconfined Compression Test, it is important to follow a specific testing procedure to ensure accurate and reliable results. This section outlines the step-by-step process involved in conducting the test.

1. Cleaning and Specimen Placement

Begin the testing procedure by thoroughly cleaning the plates used in the testing chamber. Any debris or contamination on the platens can affect the test results. Once the plates are clean, carefully place the specimen in the center of the platens, ensuring proper alignment.

2. Application of Load

The load is applied to the specimen at a specified rate using a loading device. The loading device allows for either stress-controlled or strain-controlled testing. Choose the appropriate loading method based on the testing requirements and objectives.

3. Continuous Load Application

The Unconfined Compression Test should be conducted with continuous load application. This means that the load is steadily increased until failure occurs, and data is continuously recorded throughout the testing process.

4. Stress and Deformation Data Recording

To accurately measure the behavior of the specimen, stress and deformation data must be recorded. This is achieved through the use of strain measurement devices, which capture the strain or deformation occurring during the test. Additionally, an electronic system with accurate specifications is used to record stress data.

5. Maximum Load Accuracy

The maximum load at failure is recorded with a high level of accuracy, typically with a 1% accuracy. This ensures precise determination of the Unconfined Compressive Strength (UCS) of the specimen.

Overall, the testing procedure for the Unconfined Compression Test follows a systematic approach to ensure consistent and reliable results. By adhering to this procedure, engineers and geotechnical professionals can gather valuable data for analysis and design considerations.

Results and Calculations of Unconfined Compression Test

The results of the Unconfined Compression Test provide valuable insights into the mechanical properties of rock specimens or fine-grained soils. This section focuses on the calculations involved in interpreting the test results and analyzing the behavior of the sample.

One of the primary outcomes of the test is the stress-strain diagram, which illustrates the relationship between axial stress and axial strain. This diagram allows engineers and geotechnical experts to understand how the sample behaves under compressive loading.

The peak value on the stress-strain diagram corresponds to the Unconfined Compressive Strength (UCS) of the specimen. The UCS represents the maximum compressive stress that the sample can withstand before failure occurs. It is a crucial parameter for assessing the strength and stability of the tested material.

Calculating the axial strain, diametric strain, and compressive stress involves employing specific formulas. The axial strain refers to the deformation of the specimen along its axial direction due to applied stress. Diametric strain, on the other hand, indicates the change in diameter of the sample caused by the compressive load.

The compressive stress is determined by dividing the maximum load applied during the test by the initial cross-sectional area of the specimen. This stress value helps in quantifying the resistance of the material to compression.

The modulus of elasticity, also known as Young's modulus, describes the material's ability to deform under stress. It is calculated by determining the slope of the stress-strain curve in the elastic region. This parameter provides crucial information about the stiffness and rigidity of the material.

Poisson's ratio is another important result derived from the Unconfined Compression Test. It represents the ratio of lateral strain to axial strain and provides insights into the material's ability to expand or contract perpendicular to the applied stress.

It is important to note that size corrections may be applied when analyzing test results for different sample ratios to ensure accurate and reliable assessments.

Parameter Formula Axial Strain Axial displacement / Gauge length Diametric Strain Diametric change / Initial diameter Compressive Stress Maximum load / Initial cross-sectional area Modulus of Elasticity Slope of stress-strain curve in elastic region Poisson's Ratio Lateral strain / Axial strain

Understanding and analyzing the results and calculations of the Unconfined Compression Test provide valuable insights into the behavior and properties of rock specimens or fine-grained soils. This knowledge enhances geotechnical engineering practices and allows for informed decision-making in construction and design projects.

Rock Characterization and Range of UCS Based on Rock Types

Rocks can be characterized based on their Uniaxial Compressive Strength (UCS). The strength classification ranges from very weak to very strong, with specific values for each category. Understanding the strength of rocks is crucial in various geotechnical engineering applications.

Rock Classification and UCS Ranges

Below is a classification table that outlines the different rock types and their corresponding UCS ranges:

Rock Type UCS Range (MPa) Very Weak Rocks 10-20 Weak Rocks 20-40 Medium-Strength Rocks 40-80 Strong Rocks 80-160 Very Strong Rocks 160+

As shown in the table, very weak rocks have a UCS range of 10-20 MPa and may include weathered and weakly-compacted sedimentary rocks. Weak rocks, on the other hand, have a UCS range of 20-40 MPa and can include weakly-cemented sedimentary rocks and schists.

It's important to note that these UCS ranges are general guidelines, and the actual strength of a rock may vary depending on various factors such as mineral composition, porosity, and rock structure.

Significance of Rock Characterization

Rock characterization based on UCS is essential for geotechnical engineers and geologists. It provides valuable insights into the strength and stability of rock formations, helping in the design and construction of various civil engineering projects.

By categorizing rocks based on their UCS, engineers can determine suitable construction techniques, select appropriate reinforcement methods, and assess the overall stability of slopes, rock foundations, and underground structures.

"Understanding the UCS of different rock types allows us to make informed decisions regarding excavation methods and rock support, ensuring the safety and integrity of engineered structures." - Dr. Jennifer Lee, Geotechnical Engineer

Rock characterization also aids in predicting the behavior of rocks in response to external forces, such as loading and seismic events. This information is vital for stability analysis and designing structures that can withstand the forces exerted on them.

Furthermore, knowledge of rock strength classification can inform geotechnical investigations and improve risk assessment in mining, tunneling, and geothermal energy projects.

In summary, rock characterization based on UCS helps geotechnical engineers and geologists understand the strength and stability of rock formations. By classifying rocks according to their UCS ranges, engineers can make informed decisions in the design, construction, and analysis of various civil engineering projects.

Importance of Unconfined Compressive Strength in Geotechnical Engineering

The unconfined compressive strength is of paramount importance in geotechnical engineering, especially when it comes to the design and stability analysis of various structures such as foundations, retaining walls, slopes, and embankments. This parameter provides engineers with critical insights into the strength and stability of the underlying soil or rock mass, enabling them to make informed decisions relating to construction techniques and ensuring the safety and stability of the structures being built.

Geotechnical design analysis heavily relies on the unconfined compressive strength (UCS) for estimating the load-bearing capacity of soils and determining suitable design parameters. By understanding the UCS value, geotechnical engineers can accurately assess how much load the soil or rock mass can withstand, enabling them to optimize design solutions and minimize risks associated with structural failure.

Stability analysis is another area where the unconfined compressive strength plays a crucial role. By evaluating the UCS of the soil or rock mass, engineers can determine the overall stability of slopes, embankments, and other geotechnical structures. This information forms the basis for designing appropriate slope reinforcement measures and ensuring long-term stability.

Benefits of Unconfined Compressive Strength in Geotechnical Engineering

"The unconfined compressive strength provides engineers with critical data about the soil or rock mass, allowing for informed decision-making, optimized design solutions, and enhanced structural stability."

Understanding the unconfined compressive strength is vital for successful geotechnical engineering projects. It enables engineers to:

Assess the capacity of the soil or rock mass to bear loads and determine the appropriate design parameters for structures.

Identify potential failure mechanisms and design appropriate measures to mitigate risks associated with foundation settlements, slope failures, and embankment deformation.

Select suitable construction techniques based on the strength characteristics of the soil or rock mass.

Evaluate the performance and behavior of geotechnical structures under different loading conditions and environmental factors.

With its relevance to geotechnical design analysis and stability assessment, the unconfined compressive strength serves as a fundamental parameter in the field of geotechnical engineering. By considering the importance of UCS in the design phase, engineers can ensure the optimal performance and longevity of structures, ultimately contributing to the safety and resilience of built environments.

Applications of Unconfined Compression Test

The Unconfined Compression Test is a crucial tool in geotechnical investigations, providing valuable data for various applications in construction projects. By assessing the mechanical properties of rocks and fine-grained soils, this test offers insights into soil strength and stability, aiding in the selection of appropriate construction techniques.

One of the primary applications of the Unconfined Compression Test is the determination of the unconfined compressive strength (UCS) of soils. The UCS represents the maximum axial compressive stress a soil specimen can withstand under zero confining stress. This information is vital for analyzing soil stability and designing foundations, retaining walls, slopes, and embankments.

In addition to UCS, the Unconfined Compression Test also helps determine the shear strength of soils. Shear strength is crucial for estimating the stability of slopes and assessing the potential for soil movement or failure. The test provides valuable data on the soil's resistance to sliding along a potential failure plane.

"The Unconfined Compression Test is an essential tool for evaluating soil strength and stability in geotechnical investigations."

The test's applications extend to cohesive soils, particularly those with high clay content. These types of soils are prone to strength variations due to changes in moisture content. The Unconfined Compression Test allows engineers to assess the strength properties of cohesive soils with precision, aiding in the selection of suitable construction techniques.

Furthermore, the Unconfined Compression Test is commonly included in laboratory testing programs for geotechnical analysis. Its applications go beyond construction projects, providing valuable data for soil classification, slope stability analysis, and soil behavior modeling.

Applications of Unconfined Compression Test

Application Description Foundation Design Assessing soil strength for selecting appropriate foundation types and designs. Retaining Wall Design Evaluating soil stability for designing safe and stable retaining structures. Slope Stability Analysis Identifying potential instability and assessing the safety of slopes. Embankment Design Assessing soil strength and stability for designing embankments and earthworks. Soil Classification Providing data for categorizing soil types based on their strength properties.

Overall, the Unconfined Compression Test is a versatile tool in geotechnical investigations, offering vital insights into soil strength and stability. Its applications in various aspects of construction engineering make it an indispensable part of laboratory testing programs and ensure the safety and reliability of structures.

Advantages of Unconfined Compression Test

The Unconfined Compression Test offers several advantages in geotechnical analysis. It is a cost-effective method, requiring relatively simple laboratory equipment and procedures. The test provides fast results, allowing engineers to quickly assess the mechanical properties of rocks and fine-grained soils.

One of the key advantages of the Unconfined Compression Test is its efficiency in determining the unconfined compressive strength and shear strength of cohesive soils. By applying axial stress to a cylindrical specimen, engineers can measure the specimen's load-bearing capacity and deformation characteristics.

With its simplicity and speed, the Unconfined Compression Test is a preferred choice in geotechnical engineering. It provides valuable data for construction projects, enabling engineers to make informed decisions about design analysis and construction techniques.

Advantages of Unconfined Compression Test:

Advantages Explanation Cost-effective The Unconfined Compression Test requires relatively simple laboratory equipment and procedures, making it a cost-effective method for geotechnical analysis. Fast results Engineers can quickly assess the mechanical properties of rocks and fine-grained soils using the Unconfined Compression Test, saving time in the evaluation process. Efficient for cohesive soils The test is particularly efficient in determining the unconfined compressive strength and shear strength of cohesive soils, providing valuable data for construction projects.

Overall, the Unconfined Compression Test offers cost-effective and fast results, making it a highly advantageous method in geotechnical analysis. Its simplicity and efficiency in determining the unconfined compressive strength of cohesive soils contribute to its widespread use in the field of geotechnical engineering.

Conclusion

In conclusion, the Unconfined Compression Test is a crucial tool in geotechnical engineering for conducting reliable soil analysis and ensuring the safety of structures. Through this test, engineers can obtain invaluable data on the mechanical properties of rocks and fine-grained soils, including the unconfined compressive strength, shear strength, and stress-strain characteristics.

By utilizing the Unconfined Compression Test, engineers can make well-informed decisions regarding construction techniques and design analysis. The test's simplicity, cost-effectiveness, and ability to provide fast results make it a preferred choice in geotechnical investigations. Its use in geotechnical engineering is essential for estimating the load-bearing capacity of the soil and ensuring the stability of foundations, retaining walls, slopes, and embankments.

With its ability to measure the strength and stability of soil and rock masses, the Unconfined Compression Test plays a pivotal role in geotechnical engineering. It provides engineers with the crucial information needed to design and construct safe and stable structures. Through the analysis of unconfined compressive strengths and other soil properties, this test helps ensure the integrity and longevity of various construction projects.

FAQ

What is the Unconfined Compression Test?

The Unconfined Compression Test is a laboratory test used to measure the Unconfined Compressive Strength (UCS) of rock specimens or fine-grained soils. It provides valuable data in geotechnical engineering for soil analysis and ensuring the safety of structures.

How is the Unconfined Compression Test conducted?

The Unconfined Compression Test requires careful sampling and specimen preparation. Samples are typically retrieved through drill cores and must be representative of the original rock formation. The test apparatus includes a loading device, platens, and strain measurement devices.

What are the results and calculations of the Unconfined Compression Test?

The results of the Unconfined Compression Test include a stress-strain diagram, which shows the relationship between axial stress and axial strain. The UCS is the peak value of the diagram and represents the maximum compressive strength of the sample. The axial strain, diametric strain, and compressive stress are calculated using specific formulas. The modulus of elasticity (Young's modulus) and Poisson's ratio can also be derived from the stress-strain curve.

How are rocks characterized based on the Unconfined Compressive Strength (UCS)?

Rocks can be characterized based on their Uniaxial Compressive Strength (UCS). The strength classification ranges from very weak to very strong, with specific values for each category. The classification table provides further details on rock hardnesses and their corresponding UCS ranges for a variety of rock types.

What is the importance of Unconfined Compressive Strength in geotechnical engineering?

The Unconfined Compressive Strength plays a significant role in geotechnical engineering, particularly in the design and stability analysis of foundations, retaining walls, slopes, and embankments. It provides engineers with crucial information about the strength and stability of the soil or rock mass, helping in estimating the load-bearing capacity of the soil.

What are the applications of the Unconfined Compression Test?

The Unconfined Compression Test has various applications in geotechnical investigations. It is used to assess the mechanical properties of rocks and fine-grained soils, providing valuable data for construction projects. The test helps determine the unconfined compressive strength and shear strength of soils, which are essential in analyzing soil stability and determining suitable construction techniques.

What are the advantages of the Unconfined Compression Test?

The Unconfined Compression Test offers several advantages in geotechnical analysis. It is a cost-effective method, requiring relatively simple laboratory equipment and procedures. The test provides fast results, allowing engineers to quickly assess the mechanical properties of rocks and fine-grained soils. It is an efficient way to determine the unconfined compressive strength and shear strength of cohesive soils, providing valuable data for construction projects.